About the construction system

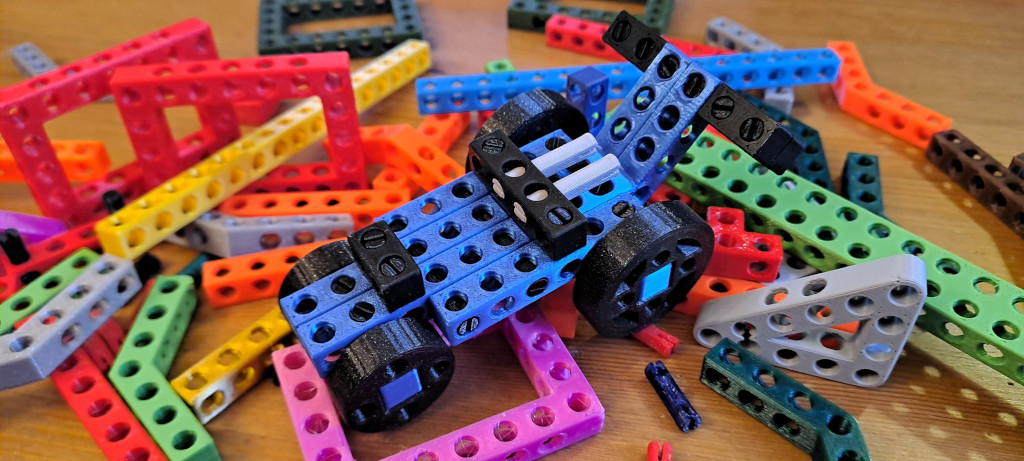

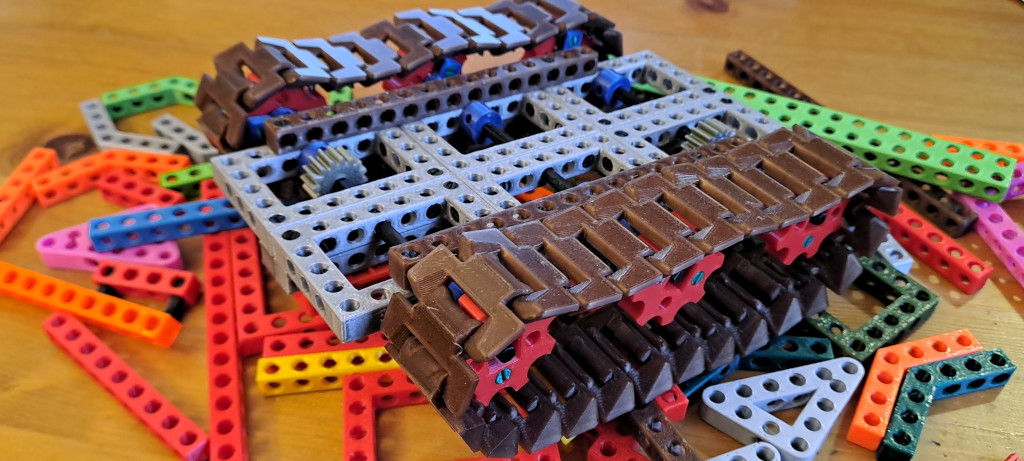

BitBeam is a modular construction system that combines versatile design with advanced technology to offer endless possibilities for building, programming, and innovation. On our website, you will find a comprehensive overview of features, components, and projects you can create with BitBeam. From simple models to complex robotic systems, BitBeam provides the flexibility and creative freedom for makers of all ages. Explore our site to learn more about how BitBeam can enhance your technical skills and open the door to new projects and experiments.

News

Download the Complete System

Want to have all BitBeam parts in one place? We have prepared a complete package of STL files ready for immediate printing. By downloading the full set, you get everything you need for your projects in one go.

Key Advantages of the BitBeam Construction System

The main benefits of BitBeam can be summarized in the following points:

- Open and Modular Design: BitBeam is based on an open Creative Commons license, allowing users to freely print and modify parts. The system is designed for easy expansion with custom components using 3D printing or other technologies.

- Compatibility with Other Systems: BitBeam parts are compatible with LEGO® Technic, making it easy to combine both systems and significantly expand your building possibilities.

- Wide Range of Applications: The system is suitable for everything from simple mechanisms to complex robotic systems. It includes various types of wheels, gears, and other specialized parts for building robots and mechanical structures.

- Educational Potential: BitBeam is ideal for STEM education, providing an interactive and hands-on way to learn programming, robotics, and engineering principles.

- Cost-Effective: Thanks to the ability to print parts at home or easily purchase them, BitBeam is an affordable alternative to other construction sets.

- Creative Freedom: Users have full control over the design and construction of their projects, fostering creativity and innovation.

How BitBeam Can Be Used

The BitBeam construction system offers a wide range of possibilities for building and programming, making it suitable for various applications:

- Robotics and Mechanical Engineering: BitBeam is ideal for building robots and mechanical models, such as robotic arms, rovers, or complex mechanisms.

- STEM Education: BitBeam is frequently used in schools to teach programming, robotics, and engineering principles. It allows students to learn through hands-on experience and develop essential technical skills.

- Prototyping and Engineering: With the ability to print parts at home and design new ones, BitBeam is a cost-effective alternative for prototyping and engineering projects. Engineers can quickly test and iterate on their designs.

- Artistic Projects: BitBeam can also be used for art projects where modular construction and creative freedom are required. Artists can create unique sculptures or interactive installations.

- Home Projects and DIY: BitBeam is perfect for home-grown projects, such as home automation or building functional models. Makers can easily design and manufacture the parts they need using 3D printing.

- Research and Development: Due to its open license and modifiable parts, BitBeam is attractive for R&D projects that require rapid testing of new concepts and technologies.

These applications are made possible by the flexibility and accessibility of the BitBeam system, empowering users to bring their ideas to life across many different fields.

Specification

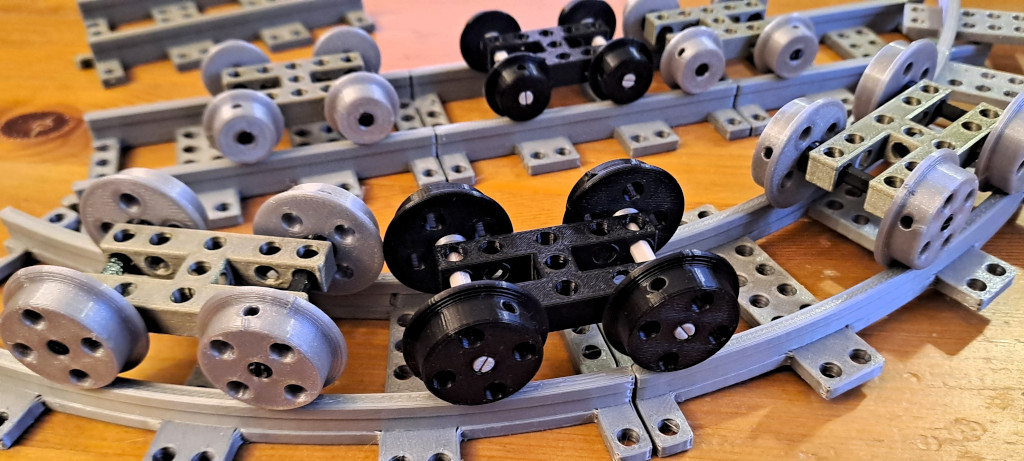

Basic unit is beam in size 8 mm x 8 mm x 8 mm. If beam has a hole, diameter of hole is 4.8 mm. Basic element to join beams to each other is screw M4, which has been replaced to 3D printed pin. Pins look like as little bit wider fork, so they holds in the holes much firmly. But it depends on used printing material, so it might be a challenge print it right.

- beam size 8 mm

- half size beam 4 mm

- hole diameter 4.8 mm

- ping size ⌀ 4.6 mm x 4 mm

- shaft size ⌀ 4.3 mm x 3.6 mm

3D printing

One of the main advantages of the BitBeam system is worry-free printing. All parts are designed from the ground up to be printed completely without additional supports and without the need for brims. This saves you time, material, and eliminates the need for tedious post-processing.

Recommended Materials:

- Basic Parts and Beams: Most commonly printed from PLA, ABS, or derived filaments. PET can also be used, though keep in mind that the parts will be more flexible.

- Gears: For these, we recommend sticking with PLA or ABS. Using PET for gears is not ideal because its flexibility increases rolling resistance and negatively affects the smoothness of the gear mechanism.

- Pins and Shafts: PET and its derivatives (PETG) are ideal for these stressed components. While they can be printed from PLA or ABS, these materials are more brittle and the parts may lack sufficient strength (they might snap under pressure). To achieve maximum durability, always print them horizontally (lying down).

- Flexible Parts: Specific components, such as tires or rollers, are printed from TPU. Keep in mind that pins hold more loosely in flexible materials, and axles may have higher friction when rotating.

Print Settings: A standard layer height of 0.2 mm is perfectly sufficient for all parts, ensuring a great balance between appearance and functionality. Coarser printing is possible, but it may not look as clean on finer details.

Links

- m-BITBEAM construction set web pages

- Learning meterials for m-BITBEAM

- Some models for construction set on Printables.com

- The original, unupdated pages by Jason Huggins

- Grid Beam construction set web pages