Gears

Whether you need rotational transmission, torque transfer at 90°, or linear motion, gears will help you achieve it. The BitBeam construction set offers a wide range of gears. In this article, we will introduce them and showcase the available mechanisms provided by the set.

Gears

Gear parts are named with the prefix gr. The basic gears are multiples of 8 and allow for gear ratios that align with the holes in the construction set. These include:

- bb-gr-8

- bb-gr-16

- bb-gr-24

- bb-gr-40

- bb-gr-56

These gears come in various versions, primarily standard and thin (th). Gears are 0.2 mm shorter than other parts to ensure smooth rotation within the set. The number in the name represents both the number of teeth and the diameter of the gear in millimeters up to half of the teeth's depth. The orientation of the gear matters: the top side is marked with small dimples. The teeth are slightly offset relative to the gear's center, enabling symmetrical attachment of other parts and facilitating easy creation of clamping mechanisms.

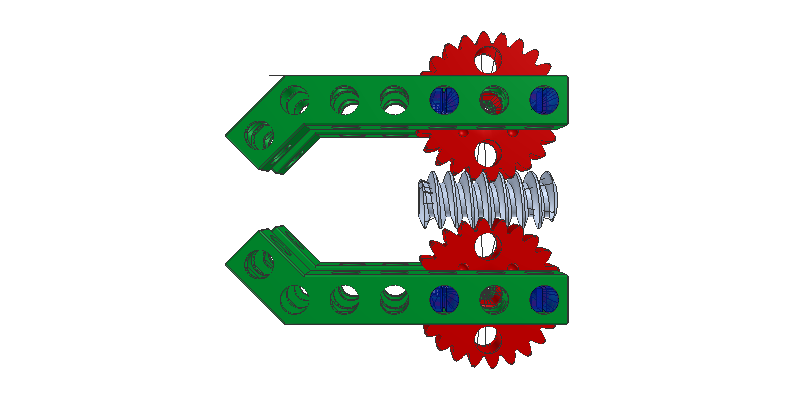

Worm gear with a 24-tooth gear forms clamps together with other construction set parts.

Gears, like other components, have a square hole in their center matching one unit size. Smaller gears also exist in versions for shafts or shafts with a plus-shaped profile (plus).

The smallest size, bb-gr-8, is too small for practical use alone. Therefore, variants exist where shafts are integrated directly into the gear.

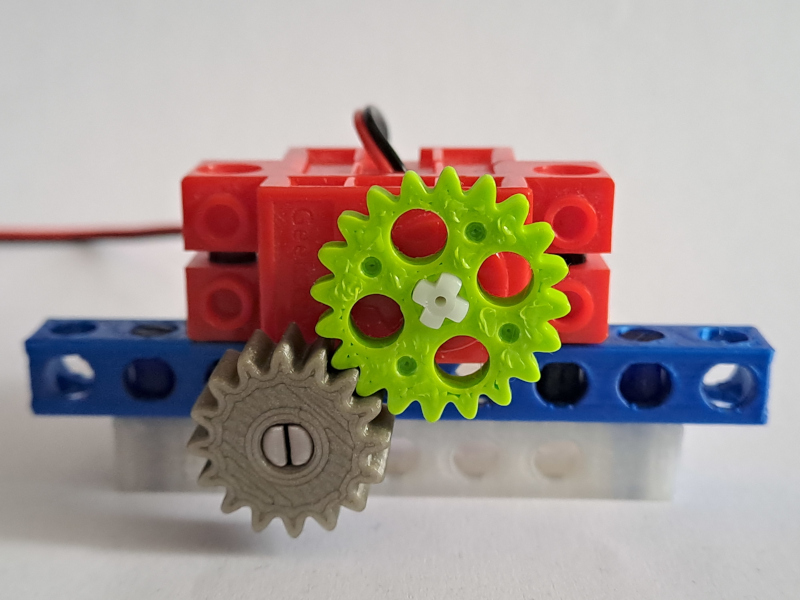

Among standard gears, there are also sizes that deviate from the regular sequence. These enable torque transfer from motors whose shafts do not align with the grid pattern of the construction set's holes. An example is bb-gr-20 and its variants.

The 20-tooth gear transfers torque from a motor whose shaft is offset from the construction set's hole grid.

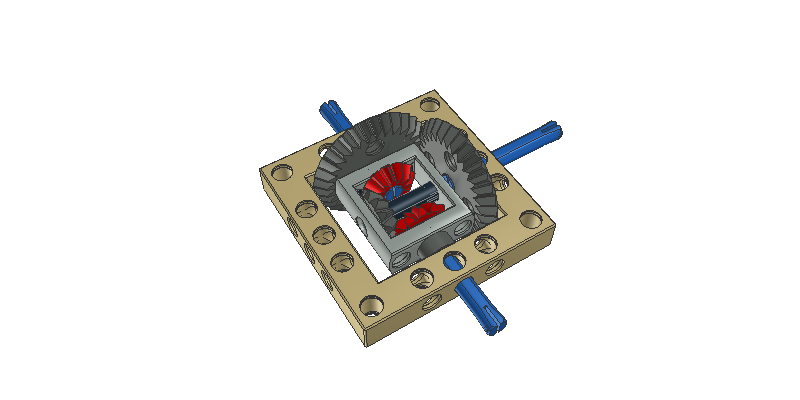

Bevel Gears

Bevel gears are used to transfer torque at right angles. To function correctly, they have different numbers of teeth and dimensions. They are available only in thin versions (th) and currently exist in two sizes. Each size includes multiple types with different hole configurations.

Bevel gears in a differential mechanism transfer torque at a 90° angle.

Internal Gears

Internal gears are circular components with internal teeth. They can serve as bases for rotating platforms or as stable points around which a gear mechanism rotates.

Large internal gears must be assembled from overlapping smaller pieces, which are also available in thin versions (th). The size bb-gr-int-408 can even be used to reinforce curved tracks.

Worm Gear and Linear Rack

The construction set also includes worm gears (worm), which are used primarily for transferring torque at 90° with very high reduction ratios. One full turn of the worm results in just one tooth movement of the connected gear.

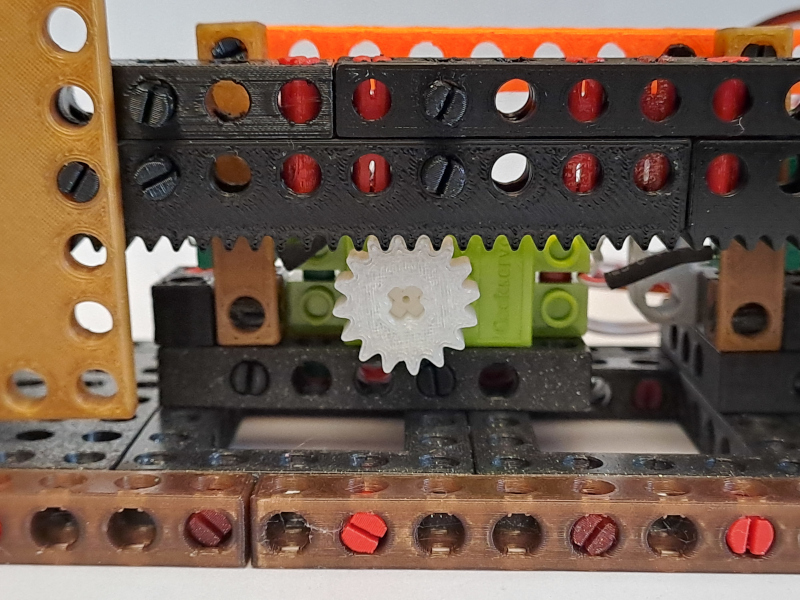

Linear racks (rack) are parts with teeth that can serve as bases for motion using gears or enable simple linear movement.

Linear transmission from a gate drive model.

Conclusion

All parts with teeth designed for torque transmission can be found in the catalog under the dedicated category Gear. Since these parts are constantly being improved, we recommend checking their latest versions before starting a new project. Gears, in particular, have undergone significant enhancements over time.