Mechanical Gripper

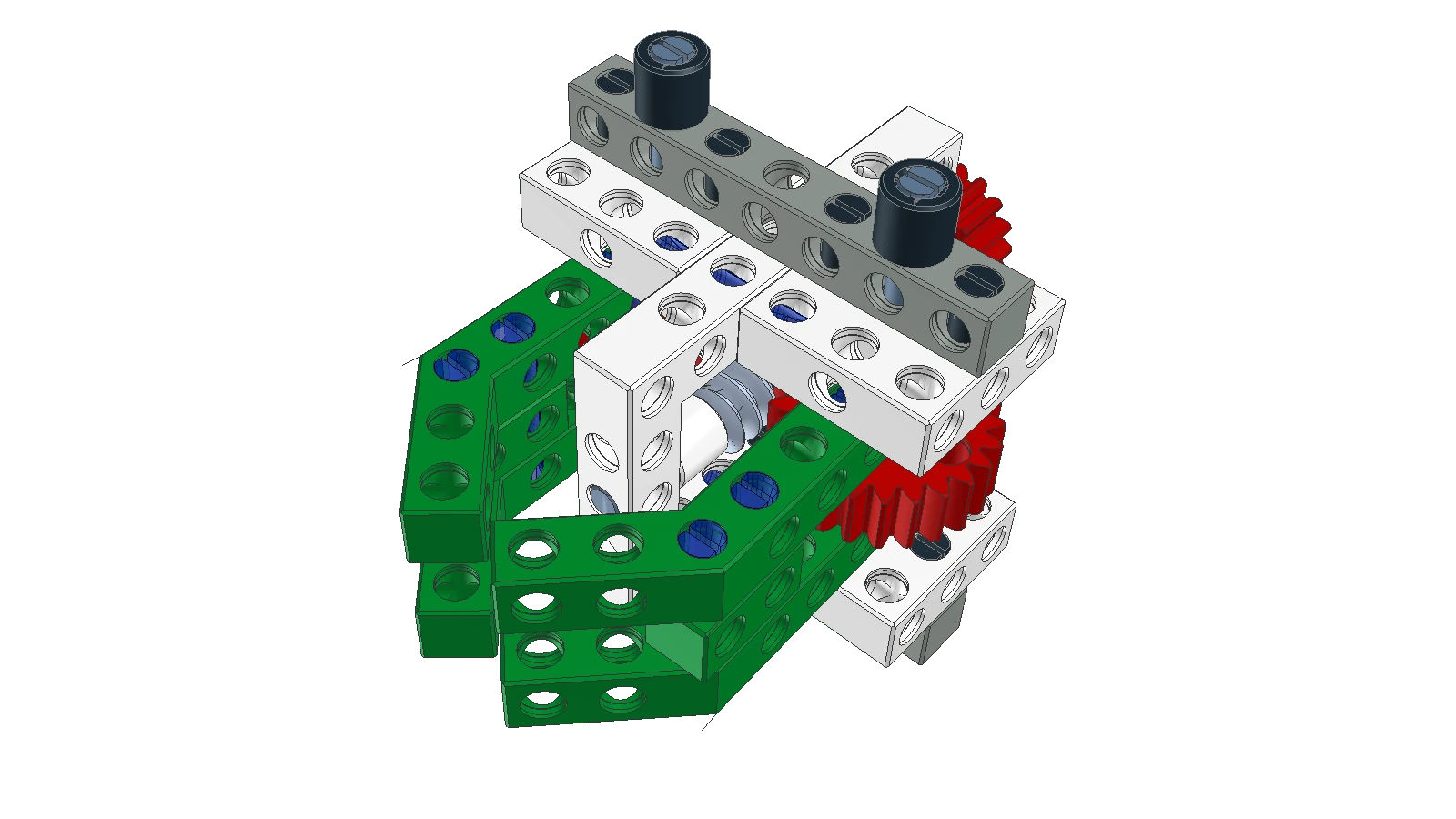

Introducing the Mechanical Gripper, a module designed as an ideal addition to projects such as a robotic arm, a mobile robot, or a tower crane. Like other BitBeam models, the gripper is designed to efficiently demonstrate fundamental mechanical principles.

The complete assembly consists of 45 parts.

Worm Gear and Jaw Movement

At the heart of the gripper is a sturdy worm gear mechanism and a clever transmission system that ensures firm and synchronized closing.

- Control: The entire mechanism is operated by rotating the worm shaft—or electronically if connected to a motor.

- Power transmission: The worm shaft rotation drives two opposing gears.

- Resulting motion: The gears are linked to the gripper arms. As the gears rotate, the gripper jaws move symmetrically toward each other, securely holding the object.

Thanks to the worm gear principle, the gripper provides high torque and self-locking properties, meaning the jaws stay closed without continuous power input.

Visualization of the assembled Mechanical Gripper.

Printing Recommendations 🖨️

We recommend printing beams and connectors from standard materials such as PLA or stronger ABS/ASA. For the worm gear components, PLA performs best. As usual, shafts and connector pins should be printed from PET-G to ensure durability and smooth motion of the mechanism.

Technical Specifications

| Parameter | Value |

|---|---|

| Length | 94 mm |

| Width | 56 mm |

| Height | 66 mm |

| Weight | 42 g |

| Load capacity | Tens of grams (depending on grip) |

| Control method | Manual / Electronic (with motor connection) |

| Number of parts | 45 |

Assembly instructions for the Mechanical Gripper are available in the PDF file gripper.pdf.

Notice

The gripper is not designed for lifting heavy loads. While the construction is stable, the maximum load capacity (tens of grams) depends on the shape, surface, and material of the gripped object. Do not overload the mechanism. Improper motor control may result in damage if the motor is not stopped in time. We disclaim any responsibility for damage caused during assembly or operation.